PTC heater elements are an excellent choice for use in wax heaters due to their self-regulating properties, which provide safety and energy efficiency. We can customize the PTC heater elements as per your request, like size, voltage and temperature. Benefits of PTC Heater Elements Key Benefits...

PTC heater elements are an excellent choice for use in wax heaters due to their self-regulating properties, which provide safety and energy efficiency. We can customize the PTC heater elements as per your request, like size, voltage and temperature.

1-Self-Regulating Temperature

PTC elements increase their electrical resistance as they heat up, which naturally limits the current flow and prevents overheating. This self-regulating feature ensures the wax melts to the desired temperature without the risk of burning or overheating.

3-Safety

Since PTC heaters limit their maximum temperature, they reduce the risk of fire hazards and provide a safer option for continuous operation.

2-Energy Efficiency

The self-regulation minimizes energy consumption once the desired temperature is reached, making PTC heaters more energy-efficient compared to traditional resistive heaters.

4-Durability

PTC heaters are generally robust and have a long operational life due to their ability to manage heat and prevent overheating.

| PTC Heater Disc | |

| Curie Temperature | 85°C |

| Voltage | 110V or 220V |

| Size | 30mm diameter |

| PTC Heating Element Chip | |

| Curie Temperature | 70°C |

| Voltage | 12V to 24V |

| Size | 10mm x 10mm |

1-Temperature Range:

Select a PTC element with a Curie temperature appropriate for melting wax, typically between 50°C to 100°C (122°F to 212°F), depending on the type of wax.

2-Power Rating:

Determine the required power rating based on the size of the wax container and the volume of wax to be melted. Common power ratings for small to medium wax heaters range from 50W to 200W.

3-Form Factor:

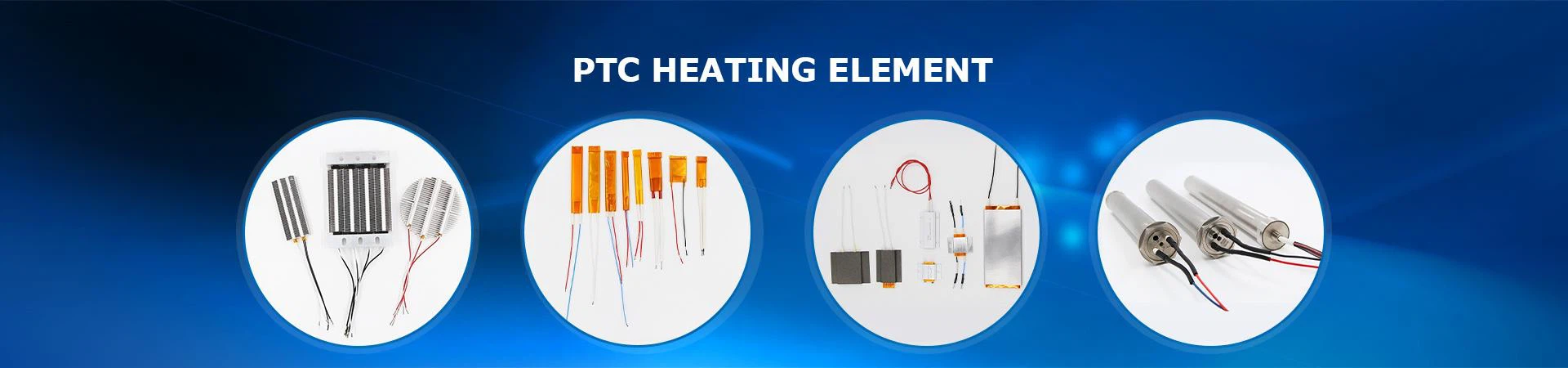

PTC heaters come in various forms, such as discs, chips, or flexible sheets. Choose a form factor that fits well within the design of your wax heater.

1-Small Wax Warmer:

A small PTC heater disc rated at 50W and 85°C could be mounted directly under a metal wax container. A simple thermostat can be added to monitor the temperature, ensuring it stays within safe limits for continuous use.

2-Professional Wax Melter:

For larger wax melting units, several PTC heating elements could be used in parallel, providing uniform heat distribution. Incorporate a digital temperature controller for precise temperature adjustments and user convenience.

Other usuage:

1-Thermal Insulation:

Ensure proper insulation around the heater element to maintain efficient heat transfer to the wax and prevent heat loss.

2-Temperature Control:

While PTC elements are self-regulating, incorporating an additional thermostat or temperature controller can provide extra precision and safety.

3-Mounting:

Secure the PTC element properly within the heater unit, ensuring good thermal contact with the wax container. Use heat-resistant adhesives or mounting brackets as necessary.

4-Ventilation:

Design the wax heater with adequate ventilation to prevent overheating of electrical components.

Hot Tags: ptc heater elements for use in wax heater, China, manufacturers, suppliers, factory, wholesale, custom, price, electric, high quality